This shoe covers are designed to protect your feet from dirt, spills, and potential infectious liquids and materials, as well as accident due to wet or dry conditions. Shoes covers are non-conductive. Available in different standard or customised sizes.

KEY FEATURES:

* Easy Slip-On Application

* Snug Fit to Protect Shoes

* Covering Shoes Part of Maintaining Sterile Environment

* Fluid and Tear Resistant Material

* Comfortable, Non-Binding Elastic

* Disposable

MANUFACTURER: TECBOD

CPE+PP Non-Woven Disposable Shoe Covers

TECBOD’s disposable CPE+PP non-woven shoe covers are multi-applications made from strong spun-bonded polypropylene that is both fluid and tear resistant. The no-slip elasticised shoe cover creates a fast and effective protective barrier for shoes. Wearing Shoe Covers are essential in maintaining a sterile environment in a hospital or surgical centre. It is also used for construction applications for protecting shoes when painting or keeping new flooring clean and free of shoe prints in new construction.

SPECIFICATION:

Raw Material: CPE PP Non-Woven Fabric

Fabric Weight: 40 gsm

Standard Size: 38cm X 15cm

Standard Packaging Quantity: 100 PCs/PP Bag

Optional Standard Colours: Blue & White, all white or customised

BENEFITS:

* Fully disposable, intended for single use

* Breathable, water-resistance material keep feet cool & dry

* Manufactured with fluid and tear resistant material

* Protective PP+CPE fabric is durable to help resist tears

* Available with integrated tread for skid resistance on slippery surfaces

* Ideal for both surgical rooms and new construction

* Non Woven Disposable Medical Shoe Covers

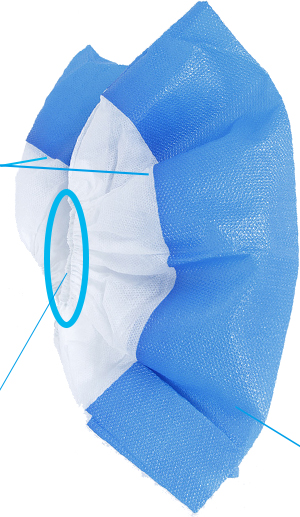

40 gsm CPE+PP Non-Woven Fabric Raw Materials

High Breathability, Class III Performance of Liquid Repellent and Penetration Resistance

Elastic Ankle

Easy Slip-On Application and Comfy Universal Fit

CPE Grid Sole

Slip-Resistance, Water-proof, Anti-Static & Tear-Resistance

|

|

|

|

|

| Medical | Cleaning Room | Industry |

Laboratory |

Food |

TECBOD is a medical textile and catheter customised(ODM/OEM) solution manufacturer. Producing process compliant to the international regulation(ISO13485) and product quality inspection base on both European and US standards.Strictly with each steps from the raw materials to the finished products, ensuring the control for the product quality, base cost and production lead time. Tailor-making solution is base on your needs and practical feedback updated by our clients(Collected from the front line professionals) after all these years! What you concern is what we concern. Let's explore more possibilities in the coming future!

|

|

|

| Raw Material Preparation | Production Process | Water Proof Film Coating |

|

|

|

| Inspection Before Packing | Sealed Packaging | Get Ready to Ship |

FAQ:

Q: What materials are commonly used to make medical shoe covers?Q: Why this type of PPE is considered essential?

A: 4 major reasons, firstly, it can protect the sterile environment as what it is. Then it will protects shoes from bodily fluids and chemical liquid splash onto the shoes.It will also help to stops the spread of bacteria. Finnally and also the most essentially is to avoids slips.

Q: Are medical shoe covers reusable?

A: No, medical shoe covers are designed for single-use only and should be disposed of after each use.

Q: How do I dispose of medical shoe covers after use?

A: Medical shoe covers should be disposed of in a designated medical waste container after use.

Q: What is the typical shelf life of medical shoe covers?

A: The shelf life of medical shoe covers varies depending on the material and manufacturer, but most have a shelf life of about two years.

Related Tags :